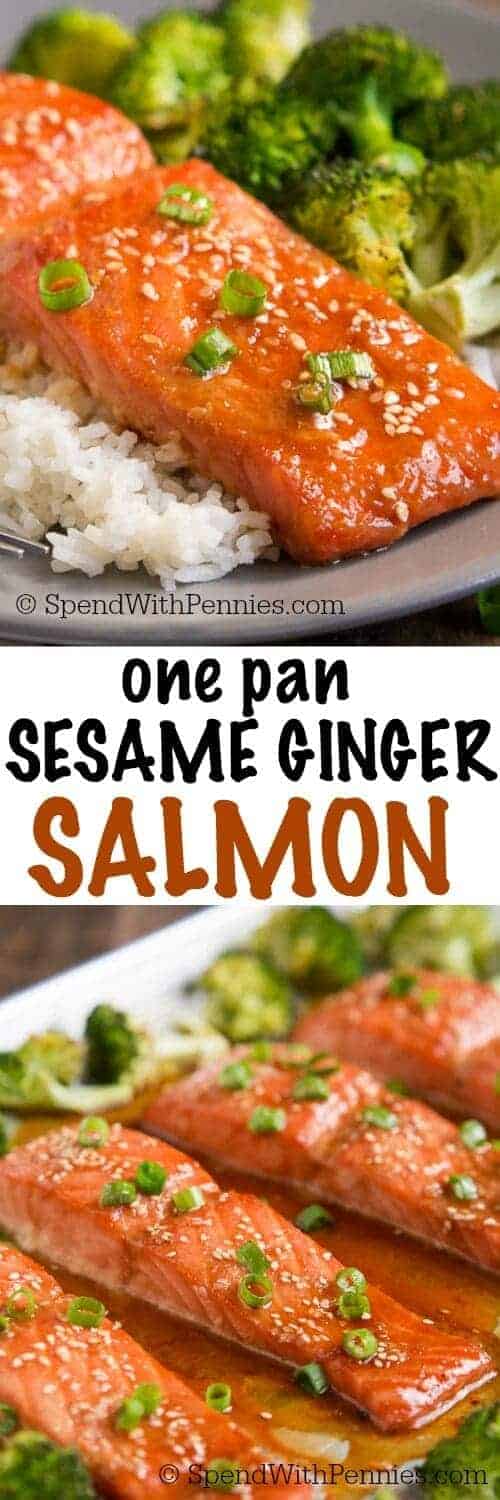

If you’re looking for a super simple healthy dish to feed your family, this sweet and tangy One Pan Sesame Ginger Salmon and Broccoli is your answer!

Salmon is one of my favorite types of fish to eat. Not only does it have great flavor and texture, it’s healthy, and doesn’t take long to prepare. This One Pan Sesame Ginger Salmon & Broccoli will soon become one of your family’s favorite recipes.

Both my daughters (only age three and one) LOVE salmon. If you have kids, you know that from one day to the next they can completely change their eating habits and likes/dislikes. One night they will hate chicken and the next night they’ll eat like a pound of it. Salmon is the one protein I can always count on them enjoying which is awesome because first, my husband and I really enjoy it; second, it’s got heart healthy fats; and third, it is so super easy for me to prepare.

Yes, you have to marinate the salmon but it’s worth it! I usually like to prep this meal the night before because I’d likely forget to prepare it during the middle of the next day. That gives the salmon extra time to soak up all those yummy flavors.

When you’re ready to prepare dinner all you have to do is start cooking some rice, pop the salmon and broccoli on a pan to bake, and stir together the glaze. 20 minutes start to finish and you can have a healthy scrumptious dinner on the table.

Add this One Pan Sesame Ginger Salmon and Broccoli to your menu to help lighten your load and enjoy a nutritious and delicious dinner.

One Pan Sesame Ginger Salmon & Broccoli

Ingredients

- 4 salmon fillets

- 2 tablespoons brown sugar

- 2 tablespoons rice wine vinegar

- 2 tablespoons soy sauce

- 1 tablespoon sesame oil

- 1 tablespoon ginger grated (I like to buy the tube of paste)

- 1 clove garlic minced

- 1 pound broccoli cut into florets

For the Glaze:

- 2 tablespoons honey

- 1 teaspoon sesame oil

- 1 teaspoon soy sauce

- ½ teaspoon grated ginger

- ½ teaspoon toasted sesame seeds

- 2 tablespoons green onions , chopped

Instructions

- Mix the marinade ingredients together and place in a bag with the salmon to marinate at least an hour.

- Preheat oven to 425°F.

- Place salmon on a greased pan and discard excess marinade. Arrange broccoli around the salmon and season with salt and pepper.

- Bake for 12-14 minutes until it flakes (145°F).

- Spoon the glaze on the salmon and sprinkle with sesame seeds and green onions.

- Serve on top of rice.

Nutrition Information

Nutrition information provided is an estimate and will vary based on cooking methods and brands of ingredients used.

© SpendWithPennies.com. Content and photographs are copyright protected. Sharing of this recipe is both encouraged and appreciated. Copying and/or pasting full recipes to any social media is strictly prohibited. Please view my photo use policy here.

Delicious recipe that looks and tastes like a very nice restaurant. Thank you!

I am so glad you enjoyed this recipe Jackie!

Just wondering why step 4 shows (145 degrees) and yet in step 2 says preheat to 425 degrees. What does the 145 degrees in parentheses pertain to?

Thanks for your help.

Janet

Hi Janet, 145°F refers to the internal temperature the salmon should reach when it becomes flaky and delicious.

I tried this… followed the recipe to a T- but I feel like the maranaide didn’t do much for the fish. The salmon still had an overly strong flavor despite the marinade. It also seems like such a waste to throw away the marinade- is there any way to boil it or something and add it into the dish?

You could most certainly boil it for a few minutes and then to thicken it, you can add a cornstarch slurry. Combine equal parts cornstarch and water (a tablespoon or so should do) and drizzle it into the boiling sauce a little bit at a time to reach desired thickness. Let us know how it goes!

Is there a size for the salmon fillets? Thanks!

A typical portion size may be 6-8 oz, but you could use whatever size you prefer!

I love salmon, but living on a budget…don’t have the extra money to buy all the ingredients your recipe call for…so i used just three ingredients that i had on hand. Was delicious! What i used. Sweet chili sauce, soy sauce and unsalted butter. Marinate for 30 minutes. Served with plain white rice and can of french style green beans…was so tasty! Thanks for throwing salmon my way!

So glad you loved it, thank you for sharing your version! Sounds delicious!

I did it yesterday and it was great! wish could add some photos on this comment so you could check it. best wishes,

Yev.

I’ve never cooked salmon before so I apologise if this is a silly question, but do you use the salmon fresh out of the refrigerator, or let it come more to room temperature?

Great question Lynne, the salmon should come closer to room temperature before cooking.

Tried the honey garlic salmon after my daughter recommended it. It was delicious as she had said. Will be trying other of your recipes. Sent link to sister in law who had been looking for other salmon recipes. She is a picky eater and needs to eat healthier for health reasons.

I’m so glad both you and your daughter enjoyed this recipe! :) Thank you for sharing with your Sister in Law!

I made the salmon this evening and it was excellent. Didn’t have fresh broccoli so I steamed frozen and drizzled the glaze over it when I served the meal. I will make this many times. Thanks.

So glad you loved this!!

Made the one pan Sesame Ginger Salmon last night for my family and it was really good! I followed recipe as is except used broccolini instead, just personal taste for this dish. Thanks for the wonderful recipe!

I’m so glad your family enjoyed this Cindy! I love broccolini,I bet it was great in this dish!

Tried the One Pan Sesame Ginger Salmon last night. My family does not usually eat fish, but this dish had them asking for more. As most cooks do I changed a few things, mainly the Vegies, but left the salmon alone. This was a good first one to try from the spendwithpennies site, thank you for such a delicious meal.

Will certainly be trying more.

I’m so glad your family enjoyed this recipe Craig!